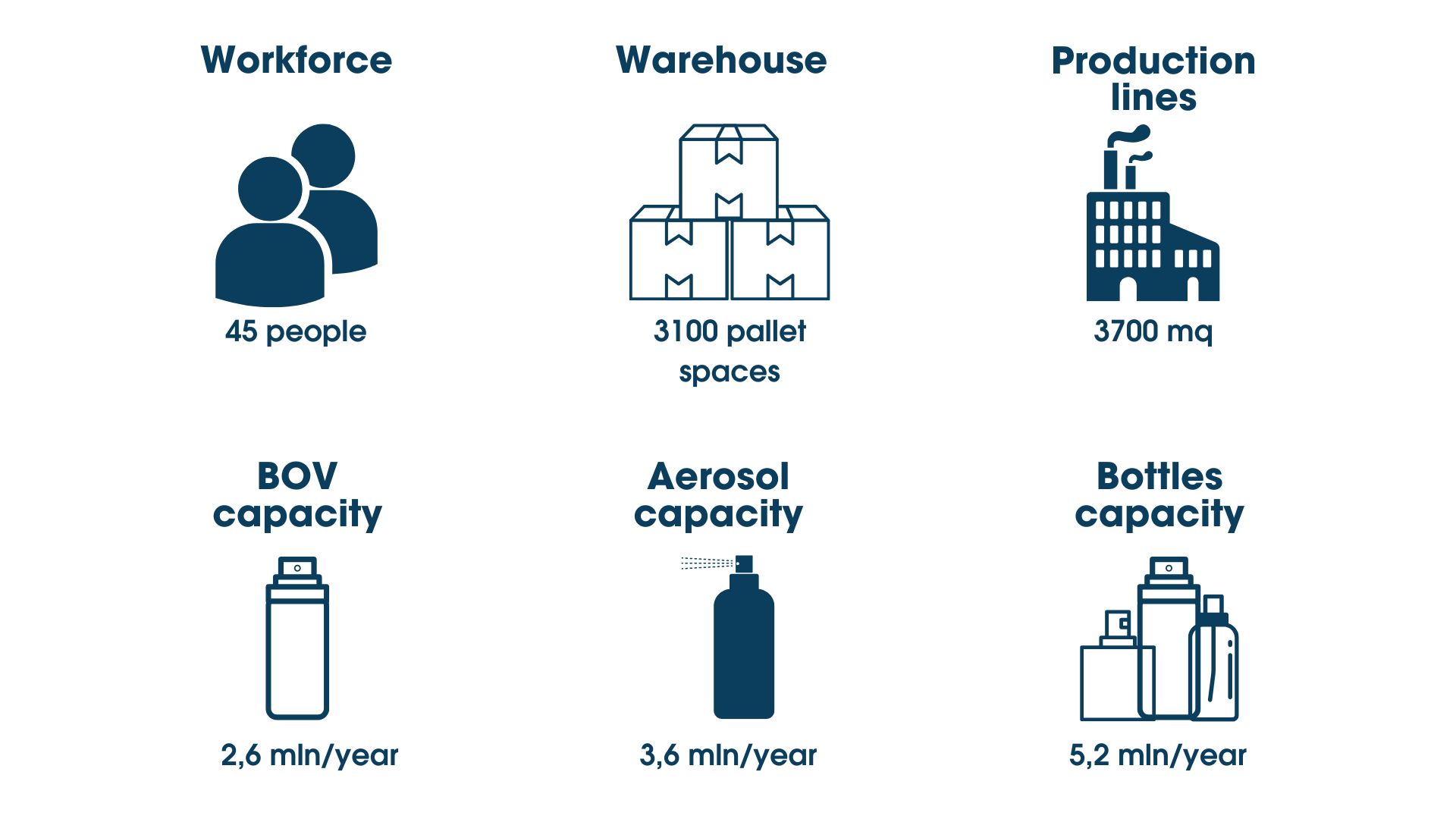

San Pietro Viminario is the state-of-the-art specifically designed facility of the group specialized in cosmetic and medical aerosol products icluding the new emerging technology bag-on-valve. The annual capacity has been increased up to 2,6 million bag-on-valve products and 3,6 million traditional aerosols.

Today the company employs around 45 people and experts strong growth in connection with the investments on a total area of 3.700 m². The company is state-of-the-art in all relevant areas that are necessary for a modern and efficient international player.

Our plant is a cutting-edge facility dedicated to crafting premium cosmetics and medical devices in aerosol form, designed to address a wide range of health and beauty needs. We harness the power of advanced technologies to unlock new possibilities, ensuring top-quality solutions tailored to our customers' diverse demands:

BOV - Bag On Valve Technology

Spray Aerosol

Pump Spray

Bag on valve technology is a new trendy packaging technology for aerosol products. The product is contained inside a bag connected to the valve, that is immersed in a non-chemical, non-flammable compressed air-based propellant that guarantees absolute safety and does away with emissions that are harmful for the environment. Traditional aerosol packaging mix the propellant and the liquid product when sprayed. With bag on valve technology, the product and the propellant are separated so only the product is dispensed.

The advantages:

The bag inside the can guarantees 100% SEPARATION OF PRODUCT AND CAN, which means tha Bag-on-Valve guarantees absolute product protection and integrity without any contamination by the propellant

BOV packaging is a HYGIENIC AND RELIABLE form of packaging: the aluminium bags ensure that the formulation is hermetically sealed. This prevents contamination and oxidation of the active ingredients to the last spray, which also contributes to the durability of the products

the product can be dispensed regardless of the container’s position: the product can be used MULTIPLE TIMES and BE ALMOST 100% USED UP

ENVIRONMENTALLY FRIENDLY, free from greenhouse gases. This is because no flammable propellants are needed, just environmentally friendly gases like air or nitrogen.

We produce aerosol sprays, using liquefied and compressed propellants, to offer maximum convenience. Our spray bottles, made of aluminium or tin plate, can be customised according to specific customer requirements, with different protective finishes and in various formats. The main advantages of this packaging system? Ease of use and continuous distribution, ensuring a seamless and always efficient experience.

Possible applications:

Body mousse

Deodorant spray

Hairspray

Dry shampoo

Sun protection

Shaving foam

The Pump Spray system is an innovative packaging solution designed to deliver a perfectly atomized mist of liquid. What sets it apart is its unique, pressure-free design in the primary packaging. The product is ejected and atomized simply by the mechanical pressure applied to the nozzle. This versatile system offers a wide range of customizable formats to meet every customer need. Whether plastic or glass, the packaging can come in any size or shape, offering limitless possibilities for your product’s presentation and functionality.

Possible applications:

sting spray

face, hair and body mist

spray conditioner

biphasic

eco hair and body spray

Our San Pietro Viminario plant specialises in the development and production of innovative sun care cosmetics. We offer broad-spectrum, water-resistant sunscreens with pleasant textures and state-of-the-art technologies that make application a unique and easy experience. Our goal is to encourage the use of sunscreen, making it a pleasant daily routine.

In addition, we strive to formulate solutions with advanced sunscreens that are as ‘ocean friendly’ as possible to protect not only the skin, but also the environment. Thus, our products boast sustainability credentials without compromising on efficacy.

Technologies:

BOV - Bag on Valve

Classic aerosol

Mousse

Cream

Serum

The site of San Pietro Viminario provides its customers with an extended portfolio of formulations dedicate to hair care in spray format.

The site has proven its expertise in hundreds of customer projects including:

Classic hairsprays

Eco hairspray

Volumizing spray

Volumizing mousse

Dry shampoo

Cosmetics

Medical Devices

Via dell’Artigianato 14 - 35020 S. Pietro Viminario (PD), Italia

Tel.: +39 0429 1701462

E-mail: marketing@biofarmagroup.it